In order to support a zero-defect philosophy and to guarantee compliant products to their customers, manufacturers have invested significant amounts of money in the last few years in their manufacturing lines. Most industries, from automotive, food, electronics to semiconductors, are concerned. Hence, manufacturers are using machine vision technology such as AOI (Automated Optical Inspection) in their production lines in on-line or off-line modes. Most of these systems are using visible cameras and/or Xray systems. Imaging solution needs to have high sensitivity and resolution at high frame rate compatible with the usage of a conveyor.

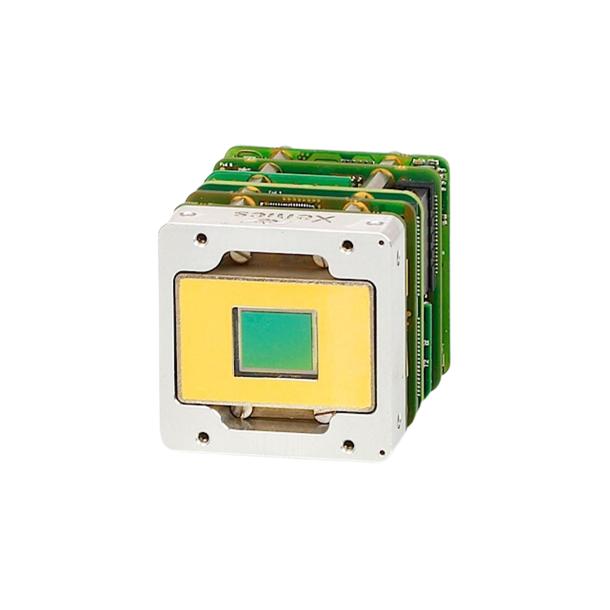

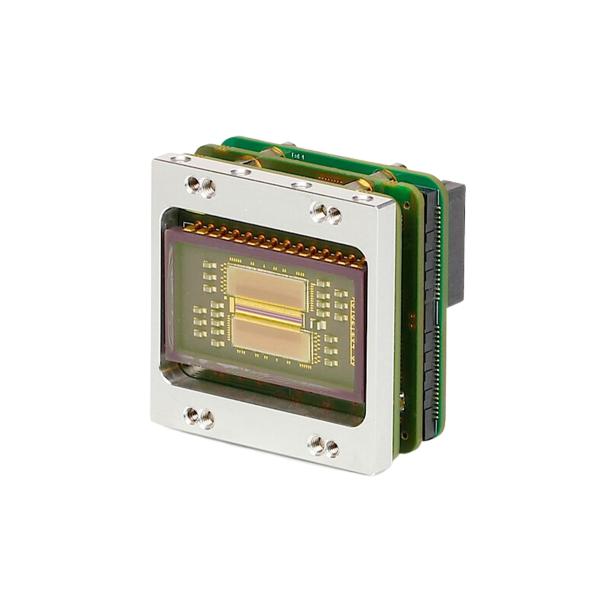

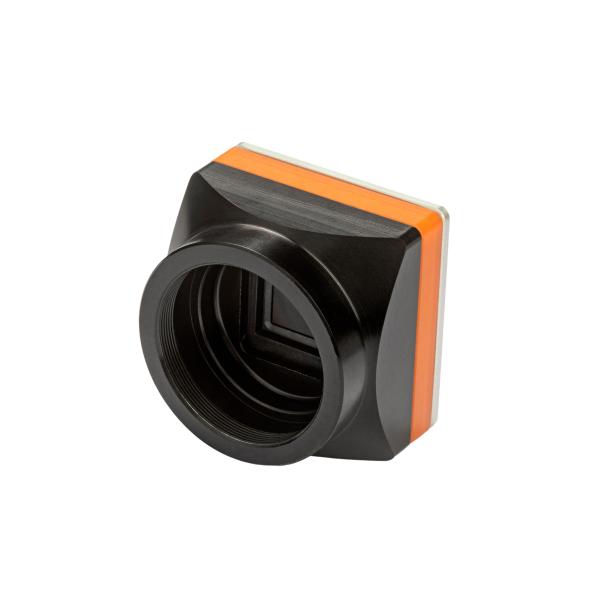

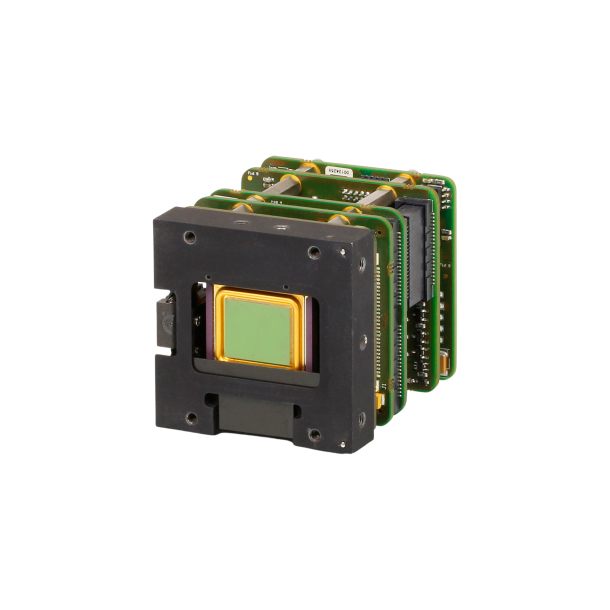

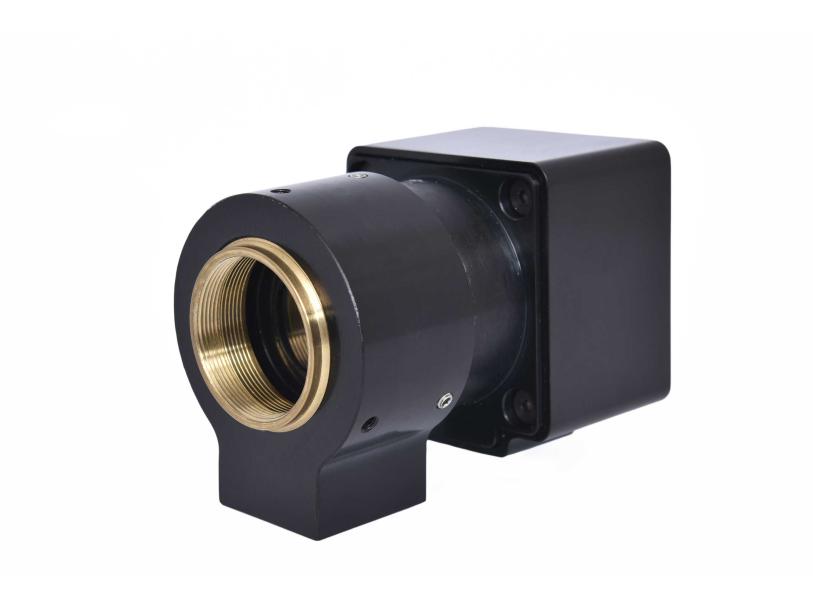

Other applications of machine vision include process monitoring, as for instance in 3D additive manufacturing. In this case, sensors need to be optimized to control in real-time the process steps. Exosens offers to OEMs and integrators intensified cameras (from Ultra-Violet (UV) to Near Infra-Red (NIR)) and infrared cameras (Short Wave Infra-Red (SWIR) or Long Wave Infra-Red (LWIR)) to support these challenges. Each bandwidth contributes to see defaults and could be used in combination in order to optimise the control efficiency. The latest Exosens imaging solutions enable to ensure a perfect product quality. Exosens cameras are compact, easy to use, with standard interfaces to be easily integrated.

Need some answers? Ask our experts!

Contact usProducts 20

See all exosens products