Phosphor Screens

Phosphor Screens for a wide range of applications: Detection of Electrons, X-Ray, UV, Charged Particles etc. Customized layer arrangement and optimization of thickness for the intended purpose. Standard format substrates on various glass types and fiber optics are available. Upon request substrates according to customer drawing or supplied by customer can be processed.

Phosphor Screens

Contact sales or request a quote

Contact usTechnical Information

| Type / Composition | P43 Gd2O2S:Tb | P43 FD Gd2O2S:Pr,Ce,F | P46 Y3Al5O12:Ce | P47 Y2SiO5:Ce | |

|---|---|---|---|---|---|

| Light Emission | Range | 360 - 680 nm | 480 - 780 nm | 490 - 620 nm | 370 - 480 nm |

| Maximum | 545 nm | 513 nm | 530 nm | 400 nm | |

| Rel. Efficiency* | 1 | 0.95 | 0.4 | 0.56 | |

| Decay Time | 90 % to 10 % | 1 ms | 4 µs | 30ns | 100 ns |

| 10 % to 1 % | 1.6 ms |

| 90 µs | 2.9 µs | |

| Excitation | Electrons | + | + | + | + |

| X-Ray | + | + | - | - | |

| UV (peak sensitivity) | + | + | + | + | |

| α radiation | + | + | + | + | |

| β radiation | + | + | + | + | |

| γ radiation | + | + | - | - | |

| Neutrons | + | + | - | - |

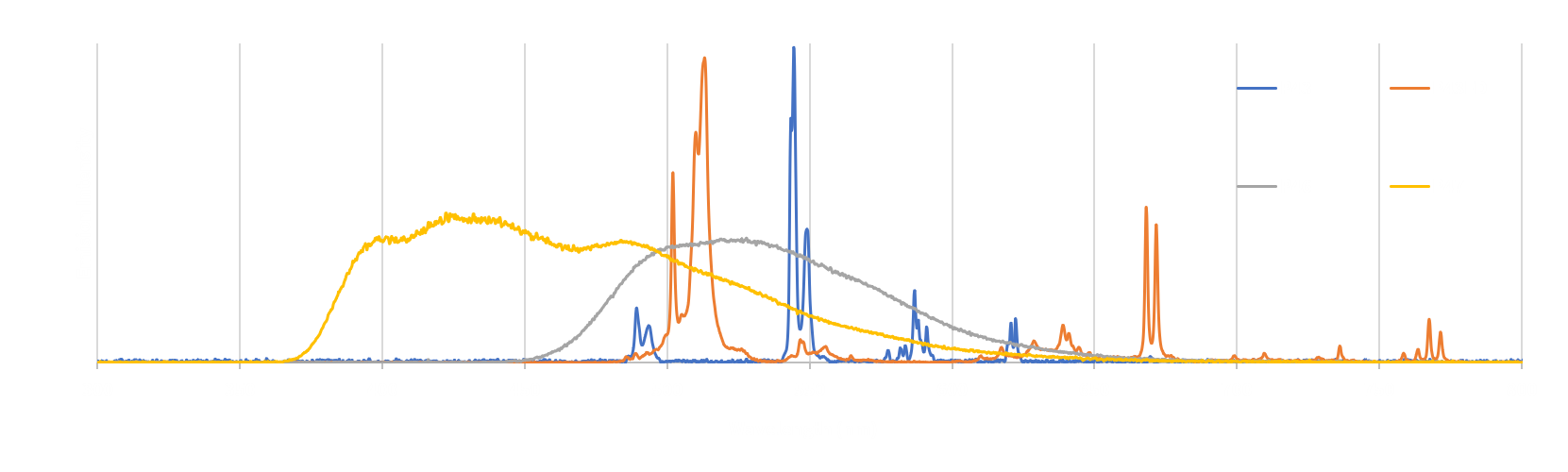

Emission Spectra

Description

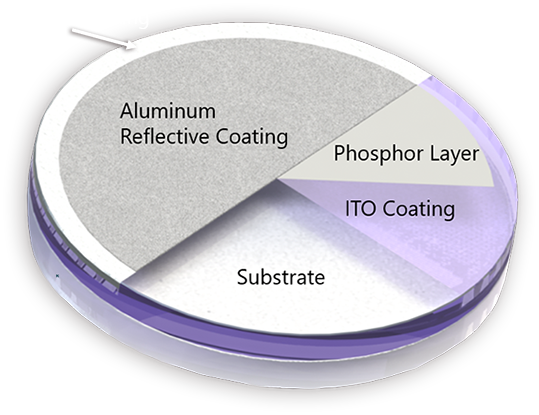

Available Additional Coatings:

ITO (Indium-Tin-Oxid)

Conductive base coating to reduce electrostatic effects caused by electrons and ions or to apply electrical potential. ITO coating is also known under the name NESA coating. Standard and special conductive parameters can be achieved.

Aluminum reflective coating

To increase light efficiency by up to 100 % and to reduce stray light, it is advantageous for most applications to seal the phosphor coating with an Aluminum layer on top of it. As a standard, a 40 nm to 50 nm coating is recommended, but on special request the thickness can be varied between 40 nm and 130 nm. For electrons, an acceleration voltage of 3 kV is required to penetrate the standard Aluminum reflection layer. With the use of an Aluminum coating, the maximum diameter for the phosphor screen is reduced by 1 mm to allow contact between the Aluminum layer and the substrate.

Chromium ring

Allowing direct electric contact to a phosphor screen, a chromium ring of width up to 100 mm diameter can be sputtered on the outer area of the substrate. This does reduce the area of the phosphor down to the inner diameter of the chromium ring.

Optional Coatings:

Water Glass

To improve the mechanic stability of a phosphor screen, water glass can be added during the sedimentation process.

A screen manufactured this way can resist a light finger touch. An efficiency decrease of 30 % to 40 % results from this manufacturing process as the density of the phosphor grains in the matrix is reduced.

Optical Marks on substrate

Reference marks on glass and fiber optical substrate according customer´s requirements.

Features

Formats: round, rectangular, prism, step plate

Substrates: various glasses, fiber optics, metal, CCD and CMOS Sensors

Phosphors: P43, P43 fast decay, P46, P47 and others upon request

Phosphor Layer: 4 - 40µm

Optional Layers: ITO, Aluminum, Chrome

Integration: Vacuum Flanges

Standard Substrates

Round, flat

| Material | Diameter/mm | Thickness/mm |

|---|---|---|

| B270 and Fused Silica | 5,0 | 1,0 |

| 20,0 | 2,0 | |

| 25,0 | 3,0 | |

| 25,0 | 3,0 | |

| 50,0 | 3,0 | |

| 75,0 | 3,0 | |

| 100,0 | 3,0 |

Round with step

| Material | Outer Diameter/mm | Step Diameter/mm | Step Height/mm | Total Thickness/mm |

|---|---|---|---|---|

| Borosilicate | 50,0 | 42,0 | 2,0 | 4,0 |

| 50,0 | 42,0 | 2,4 | 4,4 | |

| 86,0 | 77,0 | 2,4 | 4,4 |

| Material | Outer Diameter/mm | Step Diameter/mm | Step Height/mm | Total Thickness/mm |

|---|---|---|---|---|

| Quartz | 38,1 | 29,2 | 2,45 | 4,4 |

| Material | Outer Diameter/mm | Step Diameter/mm | Step Height/mm | Total Thickness/mm |

|---|---|---|---|---|

| Fiber Optic | 28,5 | 27,0 | 2,5 | 15,0 |

| 38,1 | 29,2 | 2,45 | 5,5 | |

| 42,0 | 40,0 | 2,0 | 15,0 | |

| 55,0 | 44,7 | 2,45 | 5,5 |

Prism

| Material | Length Cathetus/mm | Length Hypothenusis/mm/mm |

|---|---|---|

| N-BK7 | 20,0 | 28,3 |

| 40,0 | 56,0 |

Taper

| Material | Aspect Ratio/ mm:mm |

|---|---|

| Fiber Optic | 25:8 |

| 22:15 | |

| 25:11 | |

| 25:13,5 | |

| 40:11 | |

| 40:13,5 |